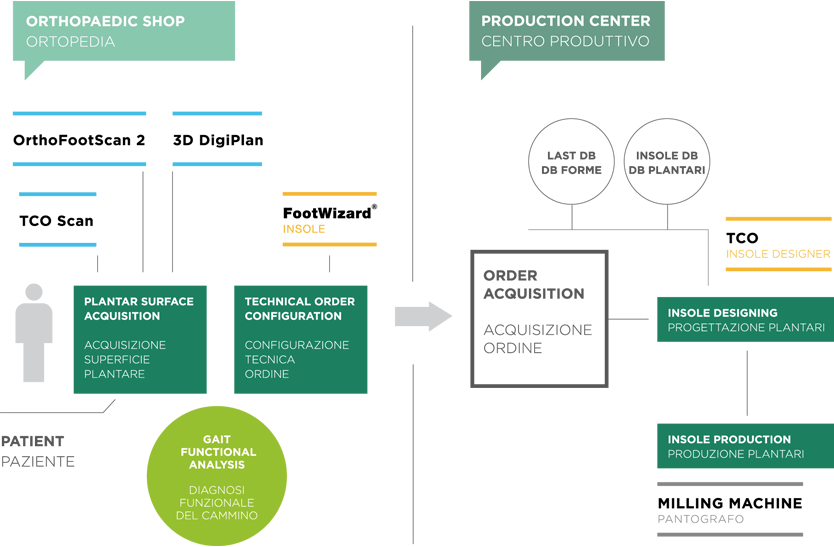

TCO – Technological Customized Orthosis – it is the innovative measure-to-manufacturing production process developed by Duna’s Innovation & Technology to innovate all the operating phases that contribute to the manufacturing of orthopaedic custom- made insole. HW e SW tools have been thought to provide the final user with a system capable to adapt to all the possible cases of daily work with efficiency and functionality, reducing to zero the necessity to operate manually on the finished product and optimizing the entire production process. The key element of the whole process is represented by the TCO Insole Designer, a 3D CAD for designing, able to integrate, even during the planning phase, the insole and the orthopaedic footwear that will guest it, maximizing the therapeutic effect and the final quality for both the operator and especially the end user. TCO is therefore a method that the Orthopaedic shop is free to perform independently or through an outsourcing scheme (design and/or production), thus defining the more suitable production process according to its necessities. The choice to operate on opened file formats has been made to allow the users to decide which and how many tools of the TCO process they might introduce in their shop